Polymeric Coagulant for Synthetic Rubbers

Coagulants are used to effectively separate fine suspended particles that cause pollution from water. Minute particles that do not readily separate from water can be separated by coagulating them into easily separated flocs.

Today, TSH-CPA series of Polymeric coagulants are absolutely indispensable as a chemical agent for environmental conservation. These are medium molecular weight highly cationic polymers used in the manufacture of Synthetic rubbers and other polymers. These are also known as cationic precipitating agents.

TSH-CPA 700 is recommended for use in the manufacture of Synthetic rubber such as SBR, NBR etc. It is very effective in emulsion breaking and production of rubber from latex. It is useful in coagulation of particles and clarification. It is particularly useful in the production of white rubber because of its low colour.

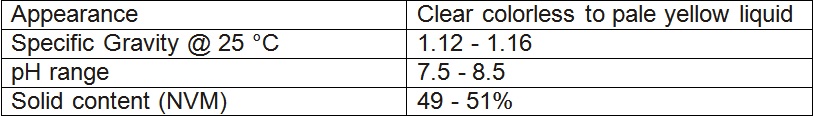

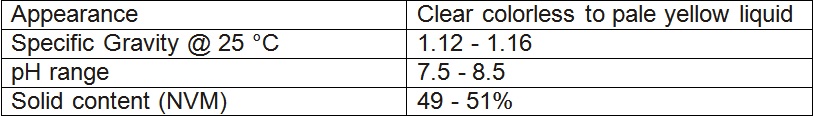

TYPICAL SPECIFICATIONS

TSH-CPA 700 is recommended as an auxiliary coagulant along with Acid-salt coagulants during manufacture of Styrene Butadiene Rubber (SBR) for improved efficiency of coagulation.

TSH-CPA 700 is highly recommended for improved efficiency of Acrylo-nitrile Butadiene rubber (NBR) from its latex as this coagulant functions in two ways:

- • At lower temperature of coagulation, it combines with the anionic emulsifier in the latex to form water soluble adduct, which passes off to the mother liquor.

- • At higher temperature (80 °C. and above) it combines with the anionic emulsifier to form an organic insoluble product, which is retained in the polymer without any harmful effect on the ultimate properties of the finished product. This insoluble product does not add to the ash content of the rubber. Therefore, the rubber becomes more non-corrosive and low mould fouling in nature, compared to the obtained using classical precipitation electrolytes.

Rubber crumbs coagulated from latex using TSH-CPA 700 are porous in nature and hence, the mother liquor can be easily expelled. Further, the rubber crumbs can be effectively washed with minimal quantity of water.

High porosity of wet rubber crumbs obtained using TSH-CPA 700 enables the rubber to be dried at lower temperatures and at a faster rate. In the process, there is considerable energy saving and increase in the production rate.

The mother liquor after separation of the coagulated crumbs is clear and hence can largely be recycled thereby saving chemical and water consumption; and also reducing load on the effluent system.

Thus TSH-CPA 700 when used in the manufacture of Synthetic rubbers would give the following benefits.

- Effective separation of polymer and aqueous layers.

- Lower dosage levels.

- Clarity of aqueous layer / mother liquor.

- Effective coagulation and faster settling.*